Our Products

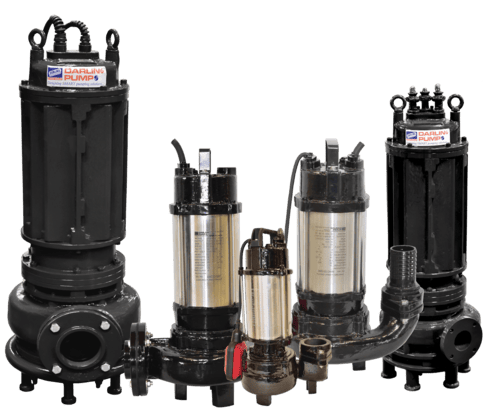

Non Clog and Waste Water Pumps

Non Clog and Waste Water Pumps

Non-clog Series Pumps

Non Clog and Waste Water Pumps

Waste Water Series Pumps

Features

- Impeller – Available in Vortex, Radial, and Channel designs to suit various solid-handling applications, capable of handling solids from a few millimeters up to 50mm.

- Motor – Highly efficient dry and wet motor options with built-in protection against temperature rise, designed to withstand wide voltage fluctuations.

- Shaft – Heavy-duty shaft to minimize deflection while pumping solids, ensuring durability and performance.

- Mechanical Seals – Seals housed in independent chambers, isolated from the pumped liquid and discharge pressure for extended lifespan.

- Bearings – Heavy-duty ball bearings at both top and bottom ends for optimal load balancing.

- Cable Sealing – Special leak-proof cable sealing system to prevent water ingress, eliminating the need to open the motor for cable replacement.

- Float Switch – Pumps up to 2HP can be provided in single-phase models with a built-in float switch for automatic operation.

Non Clog and Waste Water Pumps

Vertical Wet Pit Series Pumps

Features

- Impeller – Specially designed impeller with wide passages, capable of handling solids up to 63mm.

- Motor – Vertical flange-mounted TEFC motor, available in FLP (Flameproof) and Non-FLP variants.

- Shaft – Extra heavy-duty stainless steel shaft, designed to withstand adverse loads.

- Bearings – Heavy-duty, grease-lubricated ball bearings positioned at the top, bottom, and intermediate sections of the shaft for enhanced stability.

- Column Length – Customizable column length, ranging from a minimum of 0.5m to 6m, to suit various applications.