Our Products

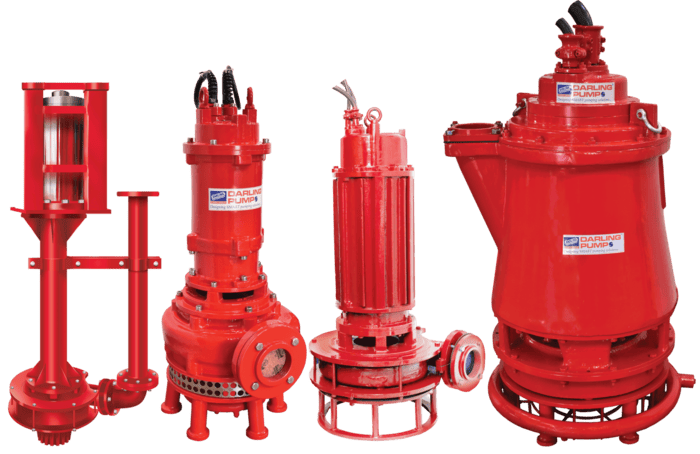

Slurry Pumps

Slurry Pumps

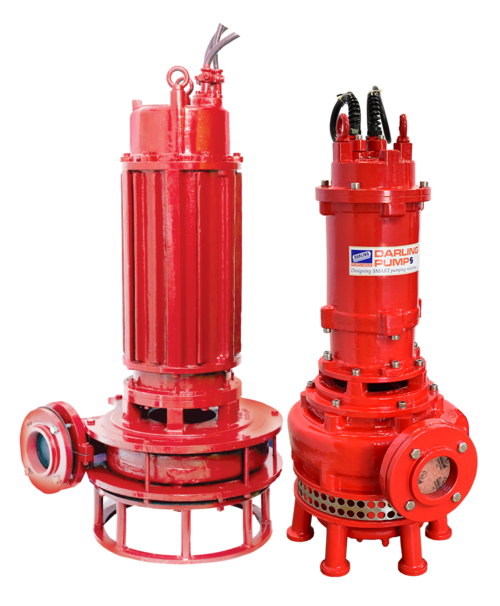

Dredger Series Pump

Features

- Impeller – Abrasion-resistant, semi-open impeller with hydraulically balanced axial thrust.

- Shaft – Heavy-duty, fully covered shaft, preventing exposure to the pumped liquid.

- Motor – High-efficiency, slow-speed motor with built-in protection against temperature rise.

- Wear Plate – Adjustable and replaceable abrasion-resistant wear plate to maintain clearances for optimal efficiency.

- Mechanical Seals – Dual mechanical seals housed in an independent chamber, free from discharge pressure, ensuring extended seal life. Additionally equipped with seal sensors to detect water ingress.

- Agitator – Built-in, abrasion-resistant agitator for efficient operation.

- Jetting – Integrated water jet arrangement for effective slurry de-settling.

- Replaceable Wear Parts – All wear components are independently replaceable, significantly reducing operating and maintenance costs.

Material

- Impeller :High Crome, Ni-Hard,hardned SS

- Shaft :SS

- Difusser :Various grades of CI/ AL/ SS

- Casing :Ni-Ci,High Crome, Hi-Hard

- Wear plate :High Crome, Ni-Hard

- Agitator :High Crome, Ni-Hard

- Mech. Seal :Sic v/s Sic, Tc v/s Tc

Slurry Pumps

4HD Series Pumps

Features

- Impeller – Abrasion-resistant, semi-open impeller with back vanes for hydraulically balanced axial thrust.

- Shaft – Heavy-duty, fully covered shaft, preventing exposure to the pumped liquid.

- Volute – Replaceable twin-volute type diffuser for enhanced efficiency.

- Wear Plate – Adjustable and replaceable abrasion-resistant wear plate to maintain clearances for optimal performance.

- Mechanical Seals – Dual mechanical seals housed in an independent chamber, free from discharge pressure, ensuring longer seal life. Additionally, equipped with seal sensors to detect water ingress.

- Agitator – Built-in, abrasion-resistant agitator for improved slurry handling.

- Jetting – Integrated water jet arrangement for effective slurry de-settling.

- Replaceable Wear Parts – Independently replaceable wear components, significantly reducing operating and maintenance costs.

- Unique Jacketed Design – Ensures maximum pumping efficiency, even in small pits, while protecting the pump from dry running.

Slurry Pumps

Cantilever Pump

Features

- Impeller – Abrasion-resistant, semi-open impeller with back vanes for hydraulically balanced axial thrust.

- Shaft – Heavy-duty, fully covered shaft, preventing exposure to the pumped liquid.

- Motor – Available in both direct-drive and belt-driven configurations.

- Bearing – Anti-friction, grease-lubricated bearings fully protected against contamination. No submerged bearings, stuffing box, or shaft seal. No need for service water flushing.

- Wear Plate – Adjustable, abrasion-resistant wear plate to maintain optimal clearances and efficiency.

- Agitator – Abrasion-resistant agitator available as an optional feature.

- Replaceable Wear Parts – Independently replaceable wear components, significantly reducing operating and maintenance costs.